Design at the earliest stages

And Simplified Product Designs

To focus effects on cost reduction

Our Services

The primary goal is helping our customers to achieve immediate results from DFMA. “I need to design products that cost less to manufacture. I need to understand the cost impact of my design choices”

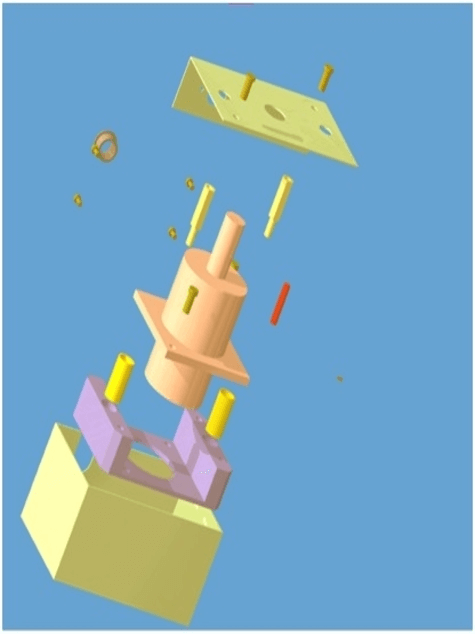

DFMA Software

DFMA Softwares guides you through an assessment of alternative processes and materials to help you generate various design proposals.

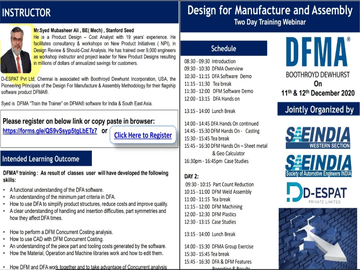

DFMA Traning

D-ESPAT has developed the DFMA Workshop/Training course to cover the basic requirements needed to successfully analyze product designs.

DFMA Consultancy

DFMA consultancy to bring out high efficiency and accurate results for your production parts and assembly designs to meet client expectations.

About Us

D-ESPAT

D-ESPAT was established to serve the domain of niche applications in the realm of engineering software applications, specially focused on Product Design review and Early Manufacturing Analysis and small, high drain, light weight environment friendly renewable Power solutions for niche applications and all Associated Technologies and businesses in these realms.

20 Years of

Business Experience

One Firm

Many Services

OUR PRINCIPAL: BDI, USA

In the early 1970s, University of Massachusetts Professor Geoffrey Boothroyd and his colleagues began research on what would become the basis for the Design for Manufacture and Assembly (DFMA®) methodology. Initially, the goal was to provide designers with a technique to quantify product designs for the ease of automatic assembly.

Products

DFA Product Simplification software utilizes an intuitive question-and-answer interface that identifies opportunities for substantial cost reduction in a product. By applying industry-tested minimum part count criteria, the software finds parts that can be consolidated/eliminated while maintaining 100% functionality.

DFA - Product Simplification

Achieve substantial cost reduction, implement concurrent engineering, and shorten product development time.

DFM - Concurrent Costing

Generate accurate should-cost estimates, evaluate supplier quotations, and benchmark competitors’ products.

Our Clients

Industry

Academic

To Experience The Most Exceptional Construction Based Consulting Services Reach Us at

Testimonial

DFMA will be helpful for analyzing the products. All the aspects of DFA &DFM & Comparison of cost of the different concepts analytically are interesting.

Shashank W

Excellent way of teaching to the point, crisp, and clear. The way of conveying topics was good. Point of interest is DFA Tool and DFM taking different processes, Concurrent thinking, & at the time out of the box approach

Jagadeesh D G

DFMA Tool is very much helpful for getting approximate cost of tooling & related process cost.

Gunasekaran L

Had very good lecture about the process and the utilization of DFMA Tool in an efficient way & Very good point to point explanation about parts of each and every field from the household product to complex industrial product.

Praveen Rajashekar Sheelvant

Smart approach towards the topic , Advancements that can be done in the real life.

Surudhi Sharma

Very deep knowledgeable instructors were deployed and the lecture was very beneficial. Being a SCM engineer DFM model was very useful and will be useful in arriving the target cost of the parts provided.

Dhivakar C

Thinking of cost of the product during concept design itself is interesting. This tool is needed for every engineer.

Senthil Kumar N

The DFMA Tool is very good for academician, Research & Manufacturing service industry. It is highly recommended to others.

Tajul Ariffin

Nice tool for innovating new ideas & costing a part to its nearest actual cost. DFMA Tool helps in improving thought process.

Ganesh K

Our Latest News & Blog