TRAINING

D-ESPAT has developed the DFMA Workshop/Training course to cover the basic requirements needed to successfully analyze product designs using the Boothroyd Dewhurst methodology. Using BDI’s Design for Manufacture and Assembly software, emphasis is placed on using the DFMA design philosophy in the design and redesign process. Hands on time with the software tools is maximized in this course.

Industrial

Academic

DFMA Training / Workshop

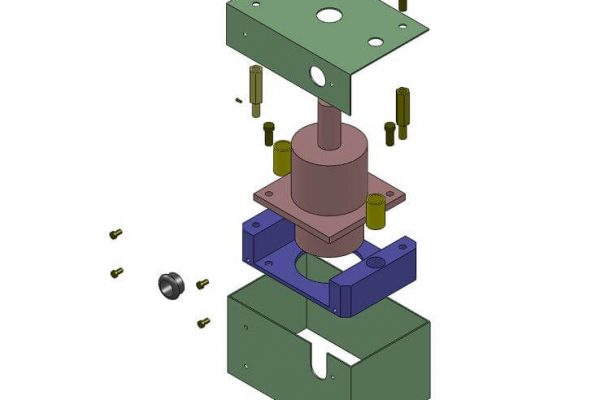

DFMA® as a design measurement technique and Software is used by Fortune 1000 companies worldwide. We introduce a new approach to DFMA training and wish to share with you for your review. It includes a Training kit called the MOTOR ASSEMBLY SYSTEM. This kit contains actual parts of a real project that have to be assembled. This MOTOR ASSEMBLY SYSTEM will have 2 kits, one present design and one revised design product. The training also introduces a systematic approach to Analyze Product Designs and introduction to manufacturing, process, materials and operations used in industry is tutored with hands-on examples for each.

- Participants to our workshop will be ready to apply the concepts & deploy DFMA software to their projects or products by the end of the training.

- This 2 day / 3 day program is to sensitize the interested participants from industry & Faculty of Engineering colleges who wish to be sensitized on the subject and evaluate inclusion in their in-house R & D projects, Design Review and manufacturing cost analysis.

The DFMA® Short Course

- The DFMA® Short Course has been developed for Faculty, Students and Industry engineers, manufacturing engineers, cost estimators and others interested in the design & production of high value products.

- The goal of the DFMA® Short Course is to demonstrate how proper consideration of part manufacturing and assembly early in the product design stage can considerably improve the overall efficiency of the value stream.

- This 2 day / 3 day program is to sensitize the interested participants from industry & Faculty of Engineering colleges who wish to be sensitized on the subject and evaluate inclusion in their in-house R & D projects, Design Review and manufacturing cost analysis.

- This 2 day / 3 day program is to sensitize the interested participants from industry & Faculty of Engineering colleges who wish to be sensitized on the subject and evaluate inclusion in their in-house R & D projects, Design Review and manufacturing cost analysis.

DFMA Training Kit

Workshop Images

Industry

Academic

About DFMA Trainer

Mr. Syed Mubasheer Ali is a Product Design – Cost Consultant facilitating consultancy, workshops on new product initiatives. A mechanical engineer, with 18 years’ experience, trained over 7,000 engineers in Creative Review & Cost Analysis as workshop instructor and project consultant for New Product Designs resulting in millions of annualized savings. A DFMA “Train the Trainer” on Boothroyd Dewhurst Methodology tool – DFMA® software