DFM Concurrent Costing

DFM Concurrent Costing software provides an immediate, thorough understanding of the primary cost drivers associated with manufacturing your product – and establishes a benchmark for what your product “should cost.” Additionally, DFM guides you through an assessment of alternative processes and materials to help you generate various design proposals.

Cost results update automatically as you specify tolerances, surface finishes, and other part details. Gradually, as you choose effective shape-forming processes and consider how to modify part features to lower cost, your product becomes cost optimized.

Benefits Of Using DFM Concurrent Costing Software

A Highly Accurate Cost-Estimator

Thanks to over 40 years of industry experience, DFM consistently provides accurate feedback on the change in cost associated with changes in parts or their design.

- Parts that are more expensive to produce than others will always yield higher cost estimates, and the amount of added expense is always correctly portrayed in the DFM results, something that historical pricing and automated CAD analysis cannot do.

- Our approach to cost analysis provides superior accuracy because it correctly identifies each step required to manufacture the part and then quantifies each associated cost.

An Easily Implemented Solution

DFM software delivers complete and accurate should-costing capability right out of the box. After installing, you gain immediate access to thousands of potential process, material, and machine combinations.

- Should you wish to add additional capabilities, you can easily create new operations and open and edit all of the existing libraries.

- Software training only takes a few days and generally results in users being completely self-sufficient in their usage. With DFM, there is no lengthy implementation or expensive customization necessary to begin enhancing your product development process.

Rather than simply providing cycle time and cost estimates, a DFM analysis educates the designer on the most important cost drivers of the proposed design. The availability of this information is invaluable when deciding how the design should be changed to reduce cost. As soon as improvements are identified, new DFM estimates can instantly be generated to get accurate results for alternative proposals.

Thanks to reliable accuracy and transparency, DFM serves as a highly effective procurement tool. The software reports all of the values and assumptions that are used to generate a cost estimate. This offers a purchasing department far more negotiating leverage than a basic quote could ever provide. With DFM, supplier negotiation is about sharing relevant data instead of using pressure tactics to lower price.

DFM allows you to benchmark a competitor’s product even when CAD models or supplier information isn’t available. An understanding of what the competing product “should cost” is gained and can be compared with the cost results for your own design. With DFM, a strategic advantage is achieved because the market feasibility for your products can be evaluated while considering the cost of your competitor’s products.

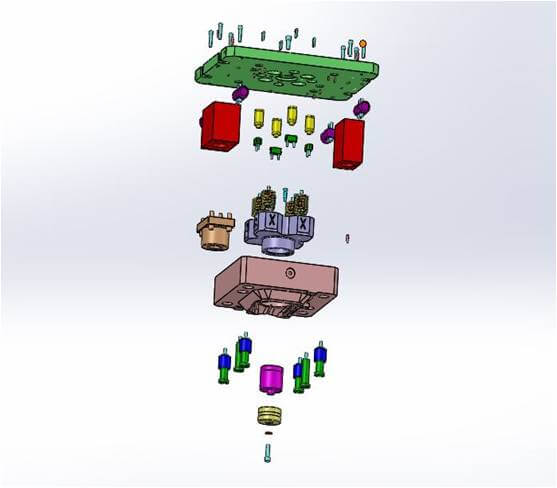

The Link To Design For Assembly

DFM complements Design for Assembly (DFA). Engineers use DFA to reduce the assembly labor within a product through the consolidation of single function parts into more elegant, multifunctional designs. The DFM software is then used to help the design engineer quickly compare the costs to produce each alternative design. Used together, the DFM and DFA software give engineers an early cost profile for each product design and provide a basis for planning and decision making. Such analyses, when performed at the earliest stages of concept design, have the potential to greatly influence manufacturing and other life cycle costs before they are solidified and become locked in place.

DFM Software Capabilites

Major Manufacturing Cost Models

Assembly Fabrication, Automatic Assembly, Blow Molding, Die Casting, Plastic Extrusion, Hot Forging, Injection Molding, Investment Casting, Machining, PCBA, Sand Casting, Sheet Metal, Foam Molding, Thermoforming, Custom User Processes, and many others fully included

- Fully Populated Operations, Machine, and Material Libraries

- Cost Breakdown, Cost vs. Life Volume Graphs

- Machining Quick Estimator

Machining Quick Estimator

Get an accurate result in minutes

Manufacturing Profiles

Get an accurate result in minutes

On Context Help System Integrated CAD Support

Select features directly from the model STL, STEP, IGES Formats